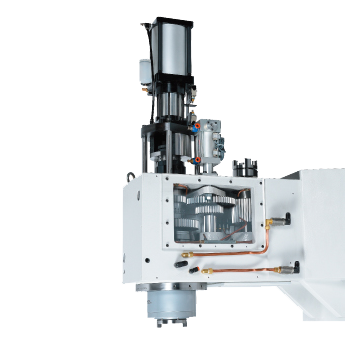

Spindle for Machining Center

The spindle for machining centers features imported precision-grade bearings, combined with accurate manufacturing and assembly techniques, achieving high precision (with nose runout within 0.005mm), high rotational speed, and low wear characteristics. The spindle nose’s waterproof and dustproof performance is optimized through flow field analysis. Finite element analysis (FEA) ensures part rigidity and structural integrity, while thermal displacement analysis guarantees structural stability and consistent quality.